Windows – Advantage through Technology

Ever wondered how technologically advanced windows are manufactured?

This video showcases what goes into the manufacturing of custom-made high performance Paarhammer windows and doors.

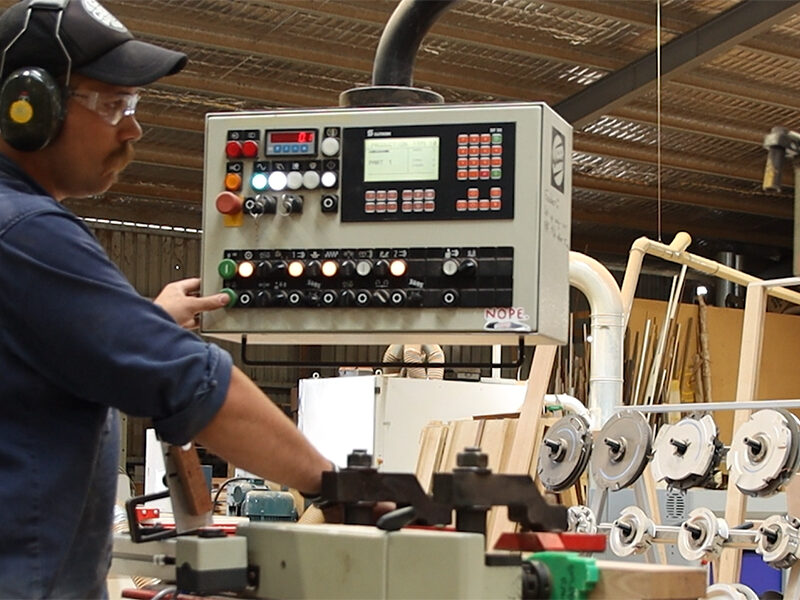

There are in fact 26 steps that custom-made windows or doors must go through before it can leave the Paarhammer factory.

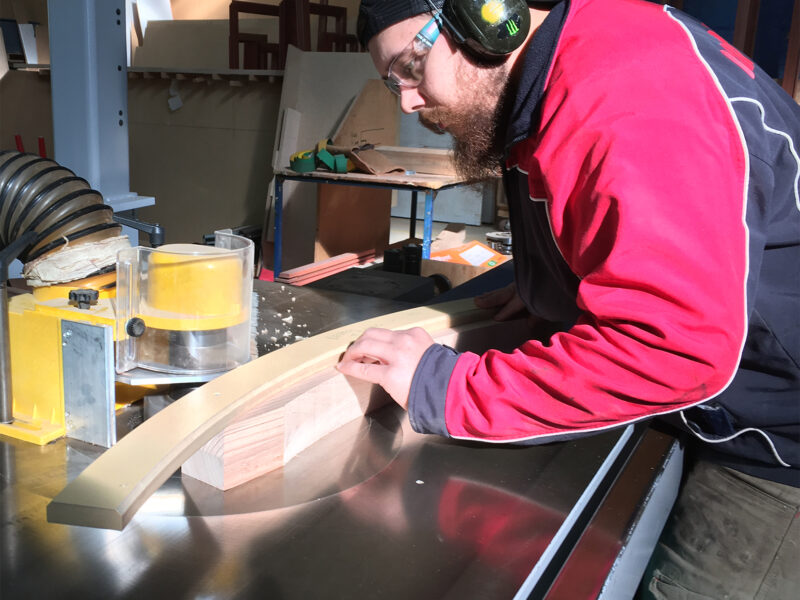

Starting with a piece of sustainably sourced timber which must be planed on all sides, cut to length and laminated together for strength and stability. Rebates, and mortise and tenon joints are next before four pieces are put together into a square.

Hinge recesses, points for mounting handles etc. are routered out, and then it gets sanded and spraypainted with low-VOC stains or paint. The next step is the inserting of the patented German hardware and seals before the sealed double or triple glazed unit gets installed. After this, every product is set up to ensure ease of operation and it gets quality checked. Careful packing and loading onto trucks complete these steps.

The windows are now ready to go on their journey to site in all different States of Australia.

Windows - Advantage through Technology