Behind the scenes at Sussex Taps

Sussex Taps was founded in the 1990s by migrated Dutchman Nicolaas Johannes van Putten, a toolmaker by trade who had a jewellery business specialising in earrings before he branched out into tapware. Today, his daughter Vanessa Katsanevakis continues his legacy from their Melbourne factory and foundry.

During the tour of the Sussex Taps factory, Vanessa greets employees as she passes through. “It’s our life,” she later explains. “So many of our staff have been here from day dot.”

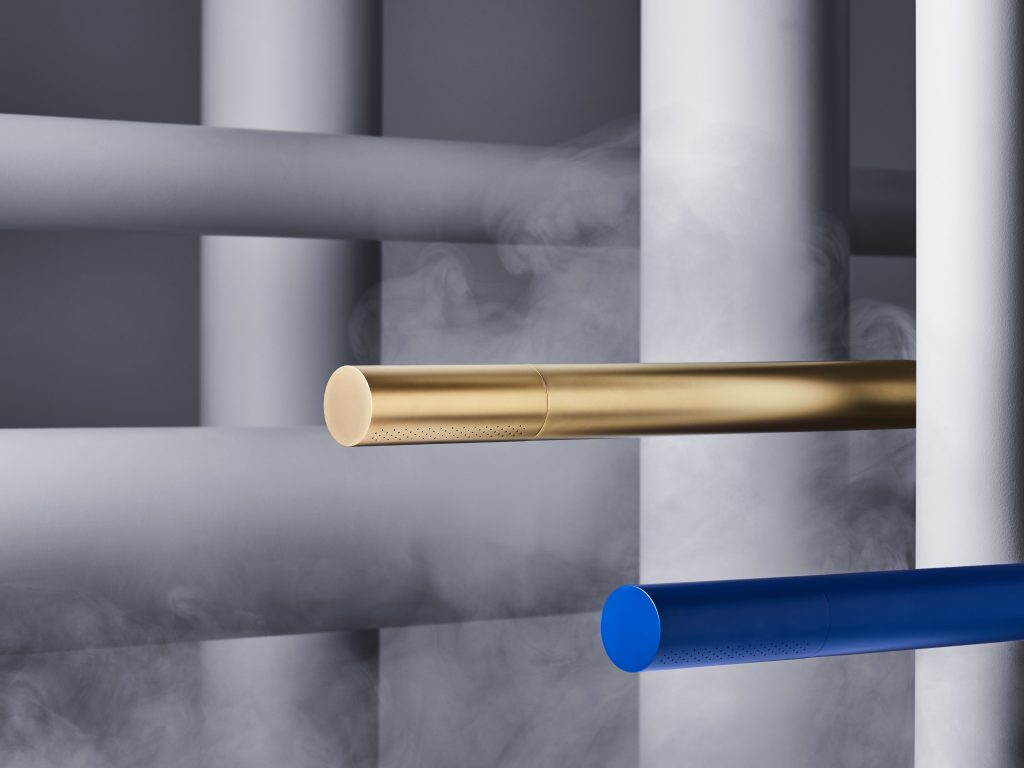

Sussex Taps prides itself on precision and quality, traits that clearly hearken back to Nicolaas’ background in jewellery making. Sussex is committed to local manufacturing, and being the only maker with an Australian foundry has distinct advantages.

The brass bars used to make the tapware are created from recycled brass shavings left over from machining operations – creating a cycle of reuse made possible by the factory and foundry’s neighbouring positions. And the convenience doesn’t stop there, says Vanessa: “The great thing is we can change. If at any point in time [we find]: ‘Oh, that sink mixer – we’ve got some issues’ … [the] Production Manager will go straight downstairs and make that change. Before we know it, we’re not getting those calls anymore. There’s that flexibility.”

Innovation is the modus operandi of Sussex Taps, and it motivates their ongoing pursuit of sustainability. “We track and monitor our energy use and we aim to reduce our consumption by 10 per cent every year,” explains Vanessa.

In 2013, Sussex did an energy efficiency audit that lead to a reduction of landfill by 20 per cent. They upgraded their foundry cooling unit which resulted in 90 per cent energy savings. “That’s 71 tonnes in carbon emissions, just by doing that upgrade,” notes Vanessa.

It doesn’t stop there. Solar panels are going up across two-thirds of the factory – some 2000-square-metres – that equate to 100kW to reduce factory carbon emissions by 30 per cent, or 131 tonnes.

While modern technology is making these goals a reality, Vanessa shares that the environment was always a priority at Sussex Taps. “My dad always dreamt – because he’s from Holland – of having windmills across the spine of the factory. He did! He planned it out, he drew it.”

“Our longterm vision is to become carbon-neutral with ISO 14001,” Vanessa elaborates.

Sussex Taps has two new collections with award-winning designers in the pipeline, so watch this space. In the meantime, Vanessa says that they’ll keep doing what they do best. “Quality, longevity … we put so much care into what we do. It’s just taps, but we care so much about them!” she laughs.

“Our taps, they’re not the quickest, they’re not the cheapest … but hopefully they can feel that care that’s gone into the product. We want it to be the best it can possibly be.”