AWS talk aluminium frames and thermal efficiency

Windows and doors are incredibly dynamic elements to a home. They need to contribute to keeping a home cool in summer, warm in winter, provide security, fresh air and natural light -whilst demonstrating a sense of finesse.

Windows react thermally via direct and indirect sunlight. When sunlight hits a window, three activities happen to the heat. Reflection is where sunlight strikes a window and some of the solar heat is reflected back. Another activity is that some of the solar heat will be absorbed. Absorption is where the absorbed heat is emitted to the outside and some is emitted inside. The final activity is where remainder of the heat is transmitted through the window into a building.

When selecting aluminium windows and doors for your home, you will often be required to comply with certain performance values for energy efficiency. The ability of a window to control heat gain is measured by the Solar Heat Gain Coefficient. SHGC is a measure of how much solar radiation passes through the window. In a cooler climate, windows which have a high SHGC allow a greater amount of solar radiation to pass through which heats up the home.

The other element to rating a window based on the frame and glass is known as the U-Value. A U-Value is the measure of how much heat energy is transferred through a window. Heat can be lost and gained through a window by the processes of conduction, convection and radiation.

The lower the U-Value, the better the window is at keeping the heat or cold out, better energy efficiency. In order to comply with energy reports, U values must be lower than or equal to what has been specified in the report.

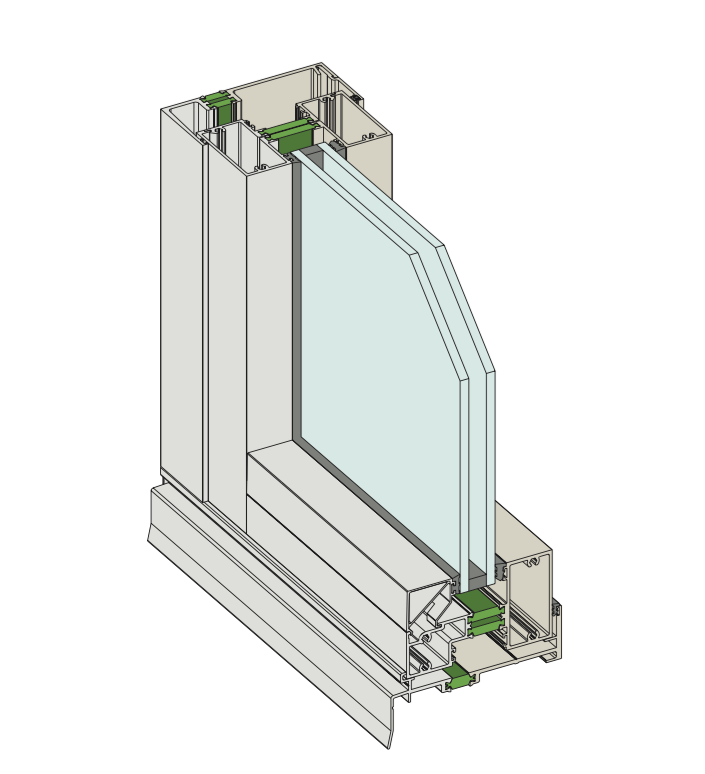

Due to the fundamental shift in the building industry toward green buildings, AWS released a Thermally Broken range of aluminium frames, known as ThermalHEART™. This range offers up to 32% better thermal performance than standard double glazed aluminium frames.

Thermally broken window frames are insulated against heat and cold conduction. This is done by separating the exterior and interior elements with a polyamide insulator. This insulator, known as the ‘thermal break’ minimises the transfer of heat and cold through the aluminium window frame. This green initiative minimises energy costs due to the reduced requirement for artificial heating and cooling systems. It is also important to note that our sensory responses to elements like temperature and light let us know if we are comfortable, and this affects our happiness

ThermalHEART™ systems are designed, tested and manufactured by Australia’s largest and most geographically dispersed network of independent window makers. This reduces the environmental burden associated with importing and transporting similar systems from overseas.

Recycled aluminium accounts for one-third of global consumption and there is scope for recycled content of global production to be increased. Aluminium can be repeatedly recycled without losing its quality. Recycling it requires roughly 5% of the original energy consumed to create it. At AWS, damaged or reject aluminium extrusions are recycled back through a remelt contractor.

Aluminium windows have the unique properties of strength, light weight, ductility and corrosion resistance. Because of the balance that needs to be achieved between energy conservation and the ideal allocation of energy rich material to appropriate end users, it has been stated that aluminium is best used on applications where its unique properties are indispensable.