narrow victory

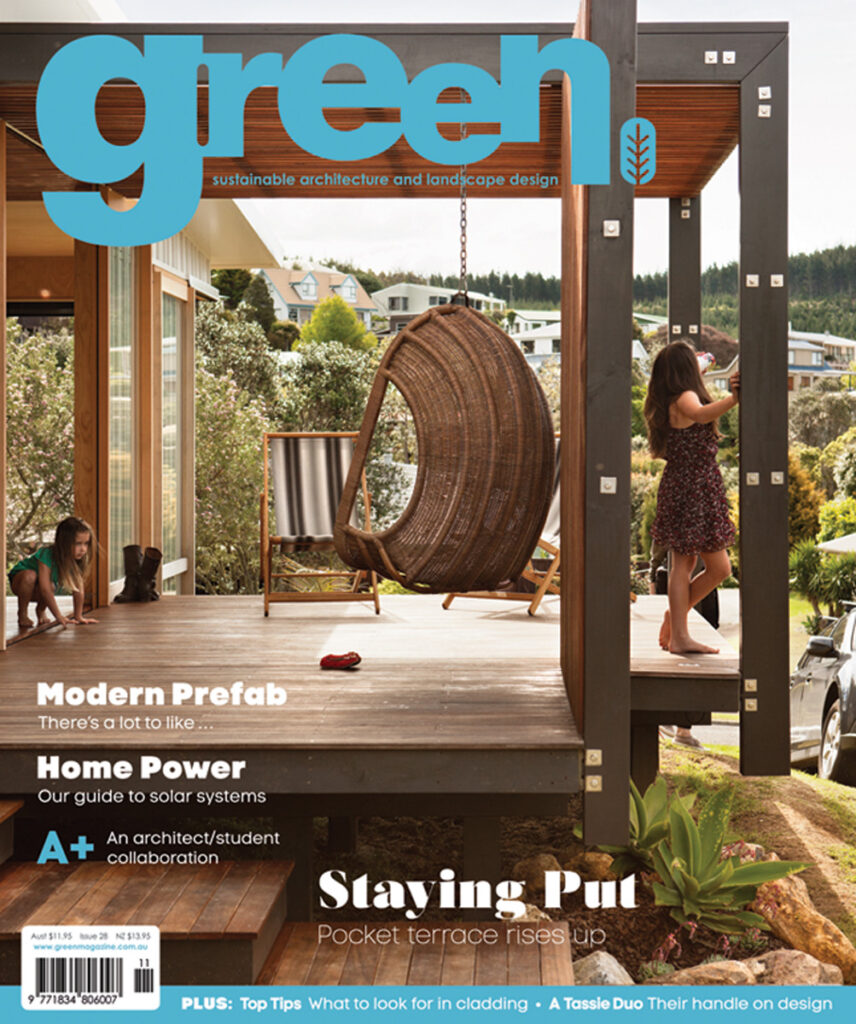

A compact yet stylish coastal “bach” on NZ’s Coromandel Peninsula was the ultimate practical assignment for a group of architecture students from Auckland’s Unitec.

When you’re crafting a home where the design-and-build team comprises 16 architecture students, two opposing idioms spring to mind. Happily this humble coastal dwelling on the Coromandel Peninsula proves the “many hands make light work” turn of phrase, rather than the “too many cooks spoil the broth” take on that theme.

Getting just the right ingredients from his young team was the responsibility of their adjunct professor at Auckland’s Unitec campus, architect Dave Strachan. A former builder, Strachan devised this hands-on module with living, breathing clients and a project that transcends drafted lines on paper to become a literal line in the sand. “It’s unique in New Zealand and a process that, among the students, sorts out the drifters from the passionate,” he says.

Understandably, when Andrew and Shiree Morrison were presented with the proposal for a group of unqualified kids to come up with the ideas for their holiday home, they were skeptical. Says Andrew: “I worried that so many people putting in their two cents’ worth were never going to reach common ground.”

Convinced to take on the challenge by their long-time friend, builder John Cocks (Cocksy), who would keep careful watch, the couple’s brief was for a small-scale, unobtrusive bach on their sloping Onemana site: “We wanted it stylish but not pretentious.” They asked for a bedroom for themselves and one for their two young daughters (Rubie and Billie) plus extra sleeping space for guests. Most importantly they wanted it all done and dusted for $120,000.

“At university, where free-thinking with no constraints is encouraged, budgets don’t come into the equation,” says Strachan. “This meant the team had to be creative – in a straitjacket.”

The students were first divided into four design groups, then into teams with responsibility to design either floor, wall-roof or the interior. In choosing the “winning” scheme, Andrew and Shiree proved the ultimate diplomats. “We ended up taking one team’s overall plan but merging a bunch of everyone else’s brilliant ideas into it.” That kept all the teams happy and engaged.

The result is a home that is a beacon to the collaborative spirit and one that steps quite naturally into a tiny green footprint. All 75 square metres of it is climate-responsive and it’s a proudly upstanding citizen in terms of materiality and energy use.

As Strachan explains: “The only way the project could be achieved on budget was to pre-fabricate the building in a factory at Unitec.” Ultimately, a two-in-the-morning tractor-hauled delivery deposited the shell on the section where the finer details of its assembly

were completed. “To the neighbours it seemed it had appeared overnight,” says Strachan. This building method meant there was no time squandered on site and less material waste.

Oriented to face north, the plan is a basic rectangle with seamless decking that lends a sense of space. A breezeway, capped by sliding doors at each end, bisects the living zone. “It’s always healthier to shift air around,” explains Strachan. “And the breezeway allows easy cross ventilation.” Louvres above the bedroom and bathroom doors add to this air-share action.

Cool in summer, the home nevertheless has textural warmth that emanates from its timber-rich make-up. The cladding is standard New Zealand pine harvested from managed forests, the wall panels are plywood, while the ceiling slats and flooring is locally grown Eucalyptus saligna.

This is partly a result of the owners’ wishes – “We always wanted to use natural wood products” – but is also to do with sustainability. “While we’ve used some aluminium in the bedrooms, mainly to give the students an experience of working with it, it’s a cold material whereas timber reduces thermal bridging which keeps the home warmer, longer,” says Strachan.

The design ticks the boxes in terms of insulation too. Solar glazing teams with fibreglass batts made from 75 per cent recycled glass to provide a snuggly blanket for the walls and under-floor. The roof, comprising two metal skins that sandwich a wad of insulation, is akin to that of a cool-store.

Natural Organ oils were used to finish the internal timbers while outdoors a water-based paint brings a sandy hue to a pattern of battens painstakingly plotted.

Of course the students were an invaluable labour resource. Although they were untrained as builders, Strachan and Cocksy kept a paternal eye on the group who sawed, hammered, sanded, painted and even laid carpet tiles. “They spent many weekends and long nights here and went way beyond what was required of the university year,” says Strachan, and Andrew Morrison adds, “We’ll never forget any of them. It was such a good bonding project.”

In the process, these ad hoc apprentices gained practical skills as well as a hard-won respect for the tradespeople they will one day work alongside. “When they draw ceiling battens on a plan, they’ll now have some sense of the physical hardship it takes to put them up,” laughs Strachan.

Lessons learnt, then, are not only about sustainability in terms of material content but in a much broader context. As Strachan points out, “You could say that giving the students the chance to work closely with clients, the council and sub-contractors is sustainable in terms of human relationships.”

Specs

Architect

Dave Strachan with Unitec Studio 19 Students and Marshall Cook. sgaltd.co.nz

Builder

Unitec Studio 19 Students with Dave Strachan and John Cocks (Cocksy).

Joiner

Interior cabinetry constructed by Unitec Studio 19 Students with the input of joiner Morgan Cronin.

Passive energy design

The house is oriented to capture the north-east sun with floor-to-ceiling glazing on east-facing rooms. The eaves control the high summer sun angles, but allow the low winter sun to have maximum penetration.

Materials

Sustainably managed and locally grown New Zealand Radiata Pine used throughout for timber piles, sub-floor/floor structure, plywood structural flooring, wall framing, SHADOWclad plywood exterior wall cladding, exterior wall cladding battens and plywood interior wall linings.

Metalcraft Thermospan Structurally Insulated Panel (S.I.P) roof structure manufactured locally in New Zealand.

Flooring

New Zealand grown Eucalyptus saligna internal “decking” to kitchen, dining and bathroom areas. Decking continues from the interior to the exterior areas off the dining room. Slatting on the ceiling mirrors this.

Interface carpet floor tiles to lounge and bedrooms; 100% recyclable.

Insulation

Roof: S.I.P roof panels R4.6 Walls: Pink Batts Ultra R2.8. High performing with a high content of recycled glass. Under-floor: EPS R1.6

Glazing

The house features a combination of Yellow Cedar framed exterior joinery units constructed by Dave Strachan and the Unitec students, and aluminum joinery units in the shower/exterior wall and bedroom (for longevity). Viridian ComfortPlus Low E glass throughout.

Ventilation

The house features operable joinery to both the warm (north-east) and cool sides (south-west) of the house, with operable louvres above all the interior doors. Natural ventilation/air convection currents are created due to the cladding heat differential between the north-east and south-west, cooling the house in summer months.

Hot water system

Rheem instant hot water system (no energy use when the bach is not occupied and no “heat-up” period related to turning on a traditional HWC on arrival).

Lighting

The house uses a combination of fluorescent and LED lighting, with limited use of halogen lighting. No recessed downlights are used.