Signed Sealed Delivered

In Australia prefabricated or modular housing is a low 5% of the market, but it’s growing. It may never be your thing, however the pros are quite compelling, as one family in suburban Melbourne discovered.

The day the “orange house” arrived at a narrow street in the Melbourne suburb of Elsternwick is now the stuff of neighbourhood legend. The street was blocked off as an enormous crane proceeded to lower the new house – which arrived in convoy on eight trucks as fully complete modules – onto site within the day with 30 workers in attendance. Talk about action stations! As Jan Gyrn, director of Modscape, the designer and builder, says with typical understatement, “Yes, they have been called ‘magic houses’.”

Only three weeks earlier, owner Jan, her husband Blair and their two children Finn (5) and Archie (4) had moved out of the Victorian two-bedroom weatherboard which previously occupied the 7.5 metre x 40.3 metre-block. Although the actual construction of the house was astoundingly fast – 12 weeks from building permit to installation – the decision to go with a prefabricated home took many years of consideration. The couple had lived in the weatherboard for 13 years but with the arrival of children they knew a decision had to be made. As Jan says, “The cottage was quite pretty but the layout was not good; it only had two bedrooms, the bathroom was small and the laundry a nightmare.”

They looked from every angle at renovating the cottage but each time they came to the same realisation: “We didn’t know how much it was going to cost,” says Jan. “And we’re not getting any younger; you have to pay off these mortgages.” Eventually the decision was made to build new. They had hoped to sell the old house so it could have another life elsewhere but the timing didn’t work out. It meant the house was demolished with the materials sold for salvage but, on the upside, two beautiful silver birch trees at the front were able to stay.

The idea of a modular house came onto their radar when they saw a container house in a magazine. Eventually it led the couple to Modscape. Operating from a large factory on the edge of the city, the company has been producing modular houses for the last six years using their own “steel frame system”. Explains Gyrn, “We use a fully-welded structural steel frame and a structural insulated panel to effectively create a thermally insulated cell. Those cells become modules, then a multiple number of modules makes up a house.” Jan and Blair’s house, for example, is eight modules: six on the ground floor, two upstairs.

Countering the argument that “prefab” houses are made to a set design, Gyrn states, “Our view is that it is simply a legitimate alternative to conventional construction. We don’t sell a particular type of house, we sell a particular type of system that can be used to create any type of house.”

It is the strength of the steel frame that allows the modules to be transported to site fully fitted with cabinetry, flooring, glazing, lighting, tiling – everything down to the toilet roll holder. Jan testifies that on installation day she received a text from a friend who happened to be driving behind one of the modules: ‘I’ve seen your kitchen and the benchtop looks awesome!’”

Although the system allows for numerous configurations, Modscape has confined its design aesthetic to a minimalist, modern style. “We’re not striving to recreate a period home. We say it’s about the future not the history so let’s design with that in mind,” says Gyrn. For Jan it was an aesthetic that clicked: “I like the modern, Scandinavian simplicity with its clean lines so it appealed to me.”

This simplicity resulted in, effectively, an orange box on top of a black box. Upstairs are three bedrooms, a bathroom, an ensuite and a walk-in robe. On the ground floor one of the fundamental design objectives was to get a connection working between the outdoor and indoor space, something that the old house failed at miserably. The site was blessed with an ideal north–south orientation with the rear facing north. As Gyrn describes it, “The entire rear elevation is basically a recessed glazed element with the appropriate amount of shading during summer but for the majority of the year it allows light to flood into the room.” Running all the way down from the front door to the rear along the eastern wall is a series of openable vertical windows. “It provides that morning light and bit of ‘dance’ along that elevation to allow the air to flow through the space nicely,” says Gyrn.

And of the head-turning front façade? Gyrn admits it was one of the biggest issues they had. The adjoining houses were both very modern while the rest of the street was a mish-mash of styles. “We looked at the setbacks and thought ‘well, what do you do here that makes it stand out?’,” says Gyrn. He recalled that Jan had specified a pink wardrobe and mentioned she liked orange, so they proposed the orange exterior for the top. “We’d been experimenting with the Alucobond ecopanels, we showed her some and she went for it. Jan has a willingness to have fun with colour, no question.”

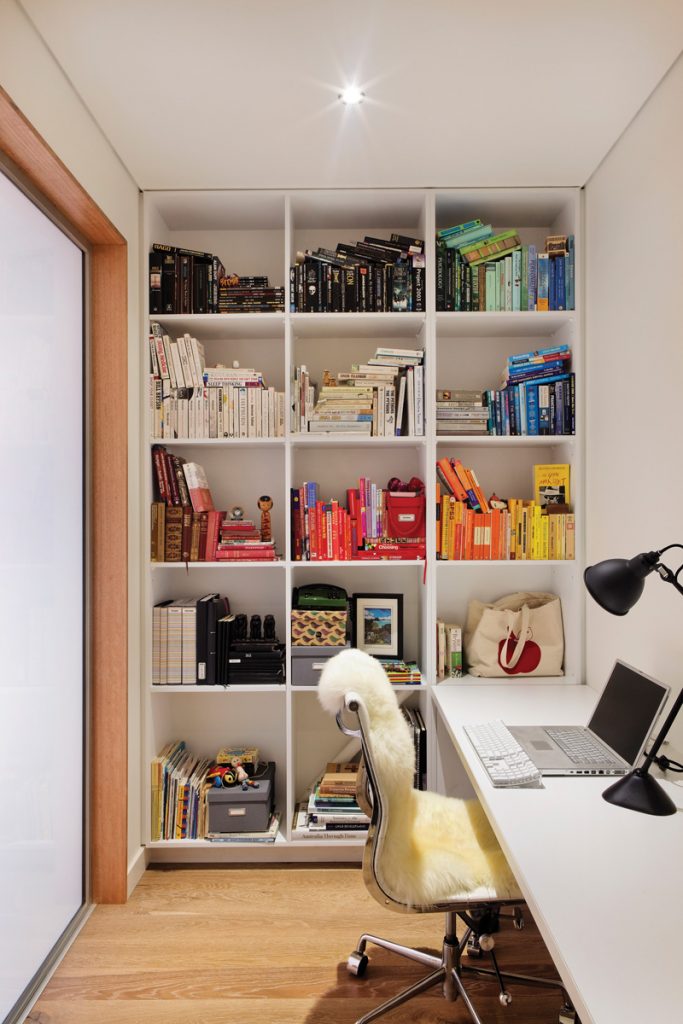

With the building/manufacturing process so rapid compared to conventional construction, it does require the client to know what they want and to be decisive. Jan came perfectly prepared for the task with a scrapbook of ideas and drawings. Apart from the bold splashes of colour throughout the house, she specified some extra cabinetry. Her expertise as a professional organiser is most clearly demonstrated by the laundry which has a colour-coded locker

for each family member where they put their daily “stuff”. As she herself admits, “This is my dream laundry – this is it!”

Aside from the ability to manage time and cost, the other advantages that Gyrn believes Modscape has over conventional construction and project homes are quality control and a focus on sustainability. “We believe construction in a factory is proven to be a more sustainable way of doing it than on site,” he says. “We recycle every bit of waste; every material is plantation, reconstituted or recycled product. There are two exceptions: the aluminium window frames and some of the steel frames, but both can be recycled at the end of the cycle for the house.” All the houses have as a standard double-glazing, LED lighting and a high level of insulation. Energy-efficient Bosch appliances for the kitchen are also standard.

Jan and family have been in the house through winter and report they’ve used almost no heating (via one small heater). “It gets down to about 14° on the coldest morning in winter – you’ve got to be happy with that. In the old house we would have the gas heating

on all night. It never warmed up, never stayed warm.” And so far on the few hot days that Melbourne has turned on the cross- ventilation has proved very efficient at cooling the house quickly. The amount of glazing has also fulfilled one of the key design briefs: to connect the inside with the outside. “I notice the weather so much more with the new house. I really love that from every room I go into I can see the sky, even in the bathroom,” says Jan.

Although Australia is lagging behind Europe, Japan and the US in its acceptance of prefabricated housing, Gyrn’s experience is of a growing market no longer confined to rural, coastal and hard- to-build sites. “What we have found is that people find it hard to build everywhere. For us it’s almost a fifty-fifty split between urban and coastal/rural.” For Jan and family, the inconvenience of living in a one-bedroom serviced apartment for five weeks was minor compared with the savings they made in rent, and the fact that the house was ready for occupation within a week or two of being craned into position. “That’s the nice part about it – it landed and was 99% there.”

Specs

Architect

Modscape modscape.com.au

Builder

Modscape

Passive solar design

The house is sited for maximum winter solar gain and shaded to exclude summer sun by utilising the north–south orientation of the block. The rear glazed elevation facing north maximises natural light while the eastern windows allow for morning light and cross-flow ventilation.

Insulation

The floor, walls and roof structure are made from a SIPS panel (Structurally Insulated Panel) that overlap to create a continuous cell. The cladding and roof sheeting then creates an air cavity with Aircell Permishield 80, R1.9 under the roof sheet.

R values achieved are Floor R2.8, Wall R3.7, and Roof R5.7.

Windows and glazing

All windows and doors are double-glazed by European Window Co.

Lighting

E-Star LED Lighting

Building materials

Ground floor – Painted EcoPly Upper floor – Alucobond ACM

Paints, finishes, appliances, fixtures and fittings, floor coverings

Low-VOC Dulux Paints Joinery is made from e-zero MDF board and Laminex.

Engineered timber flooring – Limed Oak 100% wool carpets – Feltex 4.5 star rated Bosch appliances 4.5 star rated fixtures and fittings

Hot water

The solar hot water service is a Rheem 300-litre gas boosted rooftop system.