Artful Industry

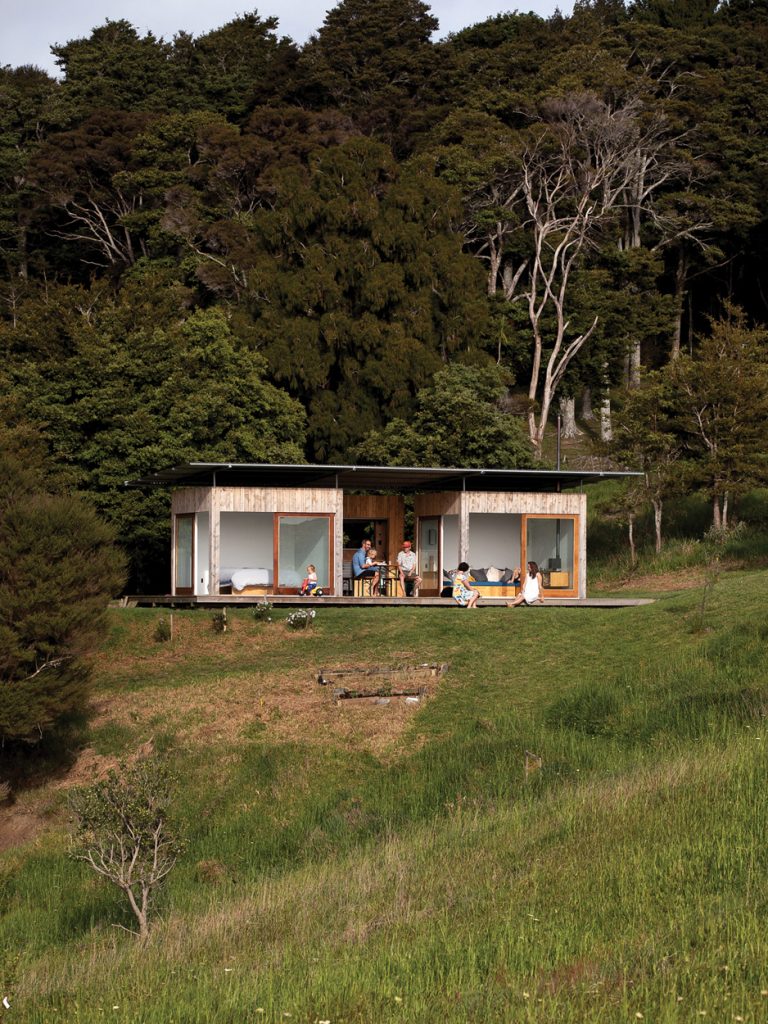

Conceived in a deal struck between client and designer, this family cabin north of Auckland honours life’s simple pleasures.

Architectural photographer Simon Wilson has an artist’s eye and a maker’s mind. So, he was well-qualified to build this holiday hut in the hills of Waipu, 90 minutes north of Auckland.

Simon and his wife, Anna MacLeod found the land – 10 acres with a peep of Taranga Island – by serendipity. “We had no previous association with Waipu but Anna has Scottish heritage and I’m a surfer and when we first drove into town, we noticed the MacLeod tartan on the welcome sign. Then there was a surfboard above the bar at the pizza barn and we thought: ‘What is this place?’”

To make it affordable, the couple, who have two children, went halves in the lifestyle block with friends who also have young kids. They plonked a caravan on the site and Simon tinkered with sketches of a structure one step up from camping. “I imagined a big tree hut.”

One day, Ben Mitchell-Anyon of Patchwork Architecture in Wellington received a call with an unusual proposal. “I’d known Simon in university days but hadn’t heard from him in 10 years,” he says. Could Ben design him a cabin in return for some photography?

The answer is the simple little building tucked into a semi circle of tõtara and manuka that may occupy a small footprint on the land but holds a huge place in the heart.

Although Simon had struggled to articulate what he had in his mind’s eye, Ben cracked the design straight away. The parameters were for it to be as cheap as chips, to be a paint-bynumbers build, and to incorporate generous cedar sliding doors that Simon had bought from a house demolition.

The width of those four doors dictated a plan. Ben placed two three metre x three metre pods next to each other on a decked platform and created centralised outdoor living and a kitchen space between them. Then he added a floating roof to unite the individual forms and provide shelter. “It came together easily,” says Ben. “The only decisions were about orientation and which way we faced the sliding doors.”

He sent Simon a digital file of the scheme and told him to get his hammer ready …

So here’s how the construction went. Picture the weekend warrior with his MacBook flipped open on the drop-saw bench, a tape measure within easy reach. Simon worked from a 3D SketchUp model, peeling back the layers to watch how the building was put together.

“It’s like a step-by-step guide and there’s even a tool that allows you to measure anything you want,” explains Ben. “For me, as a designer, having to do no detailed drawings was amazing.”

Piece by piece, over the course of a year, the real-life cabin emerged. A neighbour jumped on his tractor to help flatten the site and dig foundations. Anna and the kids, Milo (nine) and Scout (three), planted native trees to boost the natural forest. And Simon marvelled at the genius of the design’s simplicity. “There is no angle cut in the entire build. Everything is square. Even the membrane roofs are completely flat. The only angle is the pitch of the tin roof,” he says.

The one maddening part was working with the salvaged cedar sliders. “They came out of the same house but there was a 15-millimetre difference between the smallest and tallest. They were also painted pink.” Restoring them (scraping, sanding, planing, replacing the running gear) was intense.

Worth it of course, now that the hard work is done – but not forgotten. Their beautiful proportions add something special. The timber-framed cabin that gives the family a better way to enjoy the land is basic, yes, but there are moments of poetry. The macrocarpa rainscreen has rustic appeal. Made from timber that is sourced locally and harvested from farm shelter belts, it features random-width boards so there was no need to get the spacing just right. And the floating roof, a kitset of corrugated iron and galvanised pipe, lends an industrial, shed-like feel.

Between the pod that is Simon and Anna’s bedroom and the north-facing one where bench-seating doubles as a sleeping space for the kids, a kitchen slots into a one-metre-wide pod. A workbench from Bunnings with a ready-made timber top is the main component and a roller garage door pulls down when the foursome is not in residence to keep out any scavenging nightlife.

In summer though, the family is here as much as possible, enjoying the off-grid cabin and the spaces in between. Solar power runs minimal lighting, cooking uses bottled gas and the tank brims over with water collected from the roof.

This eco-conscious building was made for play and “… so our kids could be a bit silly,” says Simon. They take full advantage, using the skirt of decking that runs around the perimeter as a race track for bikes. There’s also a slide into a pond on the property for swimming if you are brave enough to take a dip with eels. And after a visit to the composting toilet some distance away, the opportunity to return by flying fox.

All up the cabin cost $50 000 and a lot of labour. “Building it was harder than expected but also one of the most rewarding things I’ve ever done,” says Simon. “Once we occupied it, I promised Anna I wouldn’t do any more building for a year.” Those 12 months are almost up. We see more artful industry in the not too distant future.

Specs

Architect

Patchwork Architecture

patchworkarchitecture.co.nz

Passive energy design

The cabins are very small and well insulated with large, glazed sliding doors facing north-east. The Zincalume and galvanised steel roof has generous overhangs on all sides to provide shading in summer and prevent the cabins from overheating. The size of the cabins means they are very easy to heat in winter but also the generous doors on two sides of each cabin mean that they can be effectively ventilated in summer.

Materials

The cabins are simple timber-framed boxes clad in plywood and then covered with a macrocarpa rain screen. Each box has a flat rubber membrane roof to catch the small amount of wind-driven rain that gets past the main roof. The doors are recycled cedar from a demolition in west Auckland. The main roof that covers both boxes is constructed with 50-millimetre galvanised pipe held together with proprietary MasterKlamp pipe fittings. The corrugated Zincalume roofing is screw-fixed to this pipe frame.

Glazing

Recycled single-glazed cedar doors.

Heating and cooling

The wood burner is a Flick wood burner, usually used in caravans and tiny houses.

Hot water system

Hot water is provided by two small instant gas heaters that run off bottled LPG. There’s one for the kitchen and one hung in the tõtara trees for the outdoor shower and bath.

Water tanks

Rainwater from the main roof is directed to a 10 000-litre water tank; the composting toilet up the hill has its own small roof and water tank for the basin.

Lighting and solar

There is only a handful of LED lights, two in each cabin, one in the kitchen and one over the dining table. These all run off a simple battery and solar panel system, which also runs a small fridge. There is also a couple of USB charging ports for charging phones, etc.

Kitchen

The main kitchen bench is an off-the-shelf tool bench from Bunnings; this has a small two-burner gas hob. There is a small, under-bench fridge that runs off the solar panels. The entire kitchen can be locked up using a Zincalume roller door when the cabins are not in use.